When purchasing springs, understanding the difference between compression and tension springs is crucial. These springs, while both helical, serve different purposes in various applications. For beginners or those new to spring terminology, knowing these differences can help make more informed purchasing decisions.

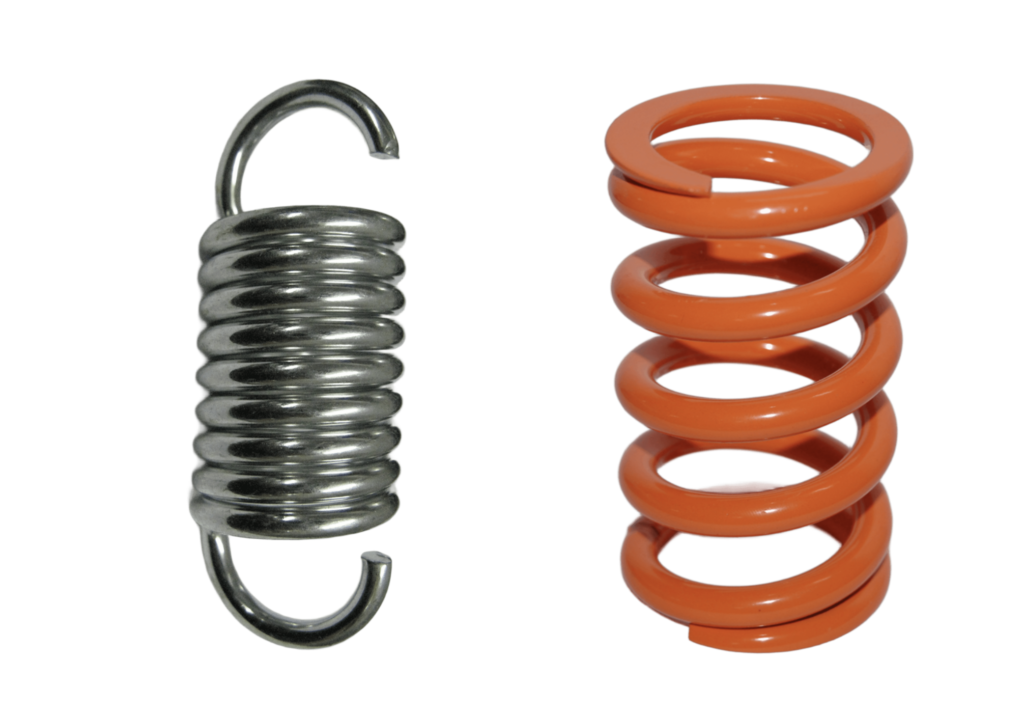

Compression springs and tension springs are both types of helical springs, but they do the opposite things. Compression springs are designed to resist force and keep things apart. They get shorter when you put a load on them. Tension springs are designed to hold things together by resisting stretching forces. They get longer when you put a load on them. It’s important to know the difference between them so you can choose the right spring for your application.

Understanding these basic functions will guide you in choosing the appropriate spring for your project, whether it involves compression or tension.

What is the difference between a compression spring and a torsion spring?

Compression springs and torsion springs, while both vital in mechanical systems, operate differently. Compression springs resist compressive forces, meaning they push back when compressed. This linear force-displacement relationship makes them ideal for applications such as automotive suspensions, where they help absorb shock and maintain the vehicle’s stability.

On the other hand, torsion springs resist rotational or twisting forces. These springs are often used in applications like garage doors or vehicle suspensions, where they store and release rotational energy. The key difference lies in their function: compression springs deal with straight-line forces, while torsion springs handle rotational movements.

What is the difference between a compression spring and an extension spring?

While both compression and extension springs are helical, their functions differ significantly. Compression springs become shorter under a load, making them perfect for applications where components must be kept apart. For instance, in pens, compression springs help push the pen tip back inside after use.

Extension springs, however, work the opposite way. They are designed to become longer under load, making them suitable for pulling applications. Commonly found in trampolines or screen doors, these springs help return the components to their original positions after being stretched. Understanding this difference is crucial when selecting springs for specific applications.

What is a compression spring used for?

Compression springs are versatile and widely used across various industries due to their ability to resist compressive forces. In the automotive industry, they are integral to suspension systems, where they absorb shocks and maintain the vehicle’s ride height. In mechanical devices, they provide the necessary pushback force to ensure smooth operation.

These springs are also used in valves, where they help control fluid flow by maintaining pressure against a valve seat. Their ability to store and release energy efficiently makes them one of the most effective energy storage devices available, suitable for a wide range of mechanical applications.

What is the purpose of a tension spring?

Tension springs are essential in applications where controlling and maintaining pulling forces is crucial. These springs are commonly used in mechanisms that require stability and precision, such as door handles, where they ensure the handle returns to its original position after use.

In trampolines, tension springs contribute to the bounce by stretching and contracting as the user jumps. These springs are also found in automotive applications, such as in the throttle return mechanism, where they help return the throttle to its idle position. The primary function of tension springs is to maintain tension between components, ensuring smooth and controlled movement.

Other Related Spring Types and Uses

Beyond compression and tension springs, there are other important spring types to consider. Torsion springs resist rotational forces and are often used in applications like garage doors and vehicle suspensions. Coil springs or helical springs can function as compression, tension, or torsion springs depending on their design and application. Understanding the specific needs of your project will help you determine the right spring type.

EASON SPRING is a professional spring manufacturer with the capability to supply high-quality compression and torsion springs. With expertise in a wide range of spring types, EASON SPRING can help you find the perfect spring for your application, ensuring durability, reliability, and performance.

Choosing the right spring type, whether compression or tension, is crucial for the functionality of your project. EASON SPRING offers high-quality compression and torsion springs, making it easier for you to find the perfect fit for your needs.